High-precision computer vision algorithms identify surface defects, structural anomalies, and visual inconsistencies in real time. ViewMetric detects cracks, scratches, dents, contamination, and manufacturing deviations with high accuracy across varying materials and lighting conditions.

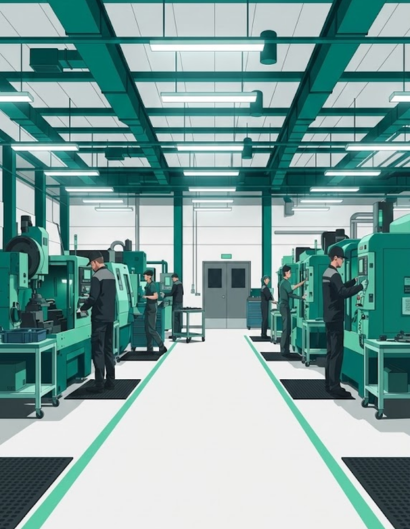

Automated Visual Inspection for Smarter Manufacturing

ViewMetric is an AI-powered computer vision inspection system that helps manufacturers detect defects, ensure quality, and automate visual inspections across production lines with unmatched accuracy and speed.

Transforming Manufacturing with AI-Powered Visual Inspection

ViewMetric is a computer vision–powered inspection platform built to help manufacturers achieve consistent quality, higher efficiency, and zero-defect production. We specialize in automated visual inspection systems that identify defects, anomalies, and deviations in real time across production lines.

- AI-Driven Defect Detection for Real-Time Quality Assurance.

- High-Accuracy Inspection Across Products, Parts, and Surfaces.

- Seamless Integration with Existing Production Lines and Systems.

Advanced Visual Inspection Capabilities for Modern Manufacturing.

AI-powered vision systems perform non-contact dimensional measurement to verify product geometry, alignment, and tolerances. Ensure compliance with design specifications without slowing down production throughput.

Dimensional Measurement & Tolerance Verification

Automated inspection verifies correct assembly sequences, component orientation, and fastening integrity. Detect missing, misaligned, or incorrectly assembled parts to prevent downstream failures and rework.

Assembly Verification & Process Validation

Real-time visual validation ensures all required components are present and correctly positioned. Eliminate missing-part errors, reduce scrap rates, and maintain consistent product quality across high-speed production lines.

Part Presence & Completeness Inspection

Why Manufacturers Trust ViewMetric for Visual Inspection

ViewMetric delivers production-ready computer vision inspection systems designed for real manufacturing environments. Our solutions combine advanced imaging, AI-driven defect analysis, and seamless line integration to ensure consistent quality, reduced waste, and higher operational efficiency across industries.

From Detection to Decision — Quality You Can Measure.

The AI Transformation Journey

We begin with a detailed consultation to learn about your business challenges, goals, and opportunities for AI integration

Discovery & Consultation

Understanding Your Needs

Data &

Feasibility

Our experts analyze your data, workflows, and technology stack

Understanding Your Needs

Development & Integration

Hear what our about customer say about our AI agency

Advances in AI Technology Are Here to Impact the Future.

Get in touch

Just fill out the form and our global experts will be in touch right away with package and price solution to help you!

Welcome to the future of artificial intelligence!

Artificial Intelligence refers to the development of computer systems that possess the ability to perform activities typically requiring human intelligence abilities!