Blog Details

- Home

- Blog Details

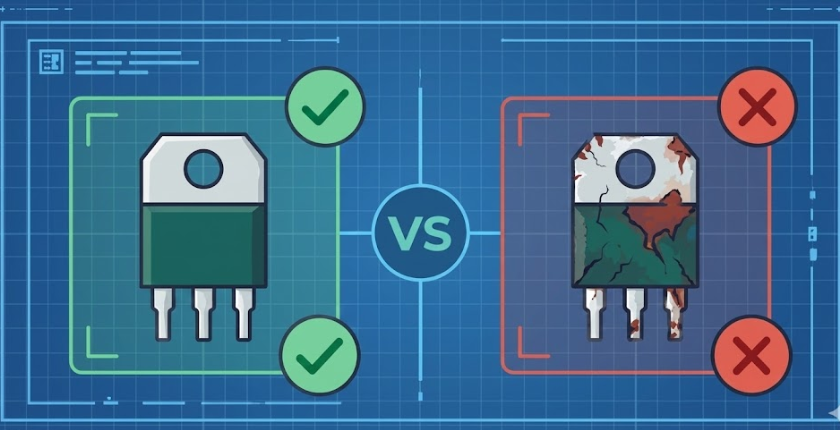

Reference-based inspection eliminates complex model training and enables faster deployment of AI-powered quality control systems across manufacturing lines.

One of the biggest challenges manufacturers face when adopting AI is the complexity of model training. Traditional AI systems require large labeled datasets, continuous retraining, and specialized expertise—making deployment slow and costly.

Reference-based inspection offers a smarter alternative. Instead of training models on thousands of defect images, the system learns from a small set of approved reference images. Any deviation from these references is flagged as a potential defect.

ViewMetric’s reference-based inspection system allows manufacturers to set up inspections quickly, even for new products or variants. This makes it ideal for high-mix, low-volume production environments where product designs change frequently.

Another major advantage is adaptability. Reference-based systems can handle variations in lighting, orientation, and material textures without constant retraining. This results in faster time-to-value and lower operational overhead.

As manufacturing moves toward agility and customization, reference-based inspection provides a scalable, efficient, and future-proof solution for AI-driven quality assurance.